Langmuir-Hinshelwood model: Acceleration by Automated Rescaling of the Rate Constants.¶

Note

To follow this tutorial, either:

Download

CoveragesAndReactionRate.py(run as$AMSBIN/amspython CoveragesAndReactionRate.py).Download

CoveragesAndReactionRate.ipynb(see also: how to install Jupyterlab)

The scale disparity issue is common in Kinetic Monte Carlo simulations. It emerges as a result of the fact that some fundamental events or groups of them typically occur at vastly different time scales; in other words, their rate constants can span multiple orders of magnitude. In heterogeneous catalysis, there are typically two groups: 1) very fast events that correspond to the species’ surface diffusions and 2) slow reactions that change their chemical identity. The latter group of events is usually the one of interest because it allows the evaluation of the material’s catalytic activity. In contrast, the species’ surface diffusion does not contribute significantly to the net evolution of the slow reactions. But, as becomes the most frequent step, it also becomes the limiting factor of the simulation progress, considerably increasing the computational cost. This tutorial shows how to speed up the calculation by several orders of magnitude without sacrificing precision by automatically detecting and scaling the rate constants of fast reactions.

We will focus on the net reaction \(\text{CO}+\frac{1}{2}\text{O}_2\longrightarrow \text{CO}_2\) that takes place at a catalyst’s surface and whose reaction mechanism is described by the Langmuir-Hinshelwood model. Because this model has four very fast processes (\(CO\) and \(O_2\) adsorption, and \(O*\) and \(CO*\) diffusion) and one slow process (\(CO\) oxidation), it is an ideal prototype for demonstrating the benefits of the automated rescaling of rate constants technique. Our ultimate goal is to investigate how altering the relative percentage of the gas reactants \(CO\) and \(O_2\) (at a specific temperature and pressure) affect the rate of \(CO_2\) production under steady state conditions. This example is inspired on Zacros tutorial What’s KMC All About and Why Bother.

Let’s start! The first step is to import all packages we need:

import multiprocessing

import numpy

import scm.plams

import scm.pyzacros as pz

import scm.pyzacros.models

Then, we initialize the pyZacros environment.

scm.pyzacros.init()

PLAMS working folder: /home/user/pyzacros/examples/ZiffGulariBarshad/plams_workdir

Notice this command created the directory where all Zacros input and

output files will be stored if they are needed for future reference

(plams_workdir by default). Typically, the user doesn’t need to use

these files.

This calculation necessitates a significant computational effort. On a

typical laptop, it should take around 20 min to complete. So, in order

to speed things up, we’ll use the plams.JobRunner class to run as

many parallel instances as possible. In this case, we choose to use the

maximum number of simultaneous processes (maxjobs) equal to the

number of processors in the machine.

maxjobs = multiprocessing.cpu_count()

scm.plams.config.default_jobrunner = scm.plams.JobRunner(parallel=True, maxjobs=maxjobs)

print('Running up to {} jobs in parallel simultaneously'.format(maxjobs))

Running up to 8 jobs in parallel simultaneously

First, we initialize our Langmuir-Hinshelwood model, which by luck is available as a predefined model in pyZacros,

lh = pz.models.LangmuirHinshelwood()

Then, we must set up a ZacrosParametersScanJob calculation, which

will allow us to scan the molar fraction of \(CO\) as a parameter.

However, this calculation requires the definition of a

ZacrosSteadyStateJob, that in turns requires a ZacrosJob. So, We

will go through them one at a time:

1. Setting up the ZacrosJob

For ZacrosJob, all parameters are set using a Setting object. To

begin, we define the physical parameters: temperature (in K), and

pressure (in bar). The calculation parameters are then set:

species numbers (in s) determines how frequently information about

the number of gas and surface species will be stored, max time (in

s) specifies the maximum allowed simulated time, and “random seed”

specifies the random seed to make the calculation precisely

reproducible. Keep in mind that max time defines the calculation’s

stopping criterion, and it is the parameter that will be controlled

later to achieve the steady-state configuration. Finally, we create the

ZacrosJob, which uses the parameters we just defined as well as the

Langmuir-Hinshelwood model’s lattice, mechanism, and cluster expansion.

Notice we do not run this job, we use it as a reference for the

steady-state calculation described below.

z_sett = pz.Settings()

z_sett.temperature = 500.0

z_sett.pressure = 1.000

z_sett.species_numbers = ('time', 1.0e-5)

z_sett.max_time = 100*1.0e-5

z_sett.random_seed = 1609

z_job = pz.ZacrosJob( settings=z_sett, lattice=lh.lattice,

mechanism=lh.mechanism,

cluster_expansion=lh.cluster_expansion )

2. Setting up the ZacrosSteadyStateJob

We also need to create a Setting object for ZacrosJob There, we

ask for a steady-state configuration using a TOFs calculation with a 95%

confidence level (turnover frequency.confidence), using four

replicas to speed up the calculation (turnover frequency.nreplicas);

for more information, see example Ziff-Gulari-Barshad model: Steady

State Conditions. Then, we ask for the rate constants to be

automatically scaled (scaling.enabled) using an inspection time of

0.0006 s (“scaling.max time”). In a nutshell, the scaling algorithm uses

this maximum time and the original rate constants to execute a probe

simulation. From there, the occurrence rates for each reaction are

determined and scaled appropriately. Only reactions that are proven to

be quasi-equilibrated are modified. The actual simulation is then

started from the beginning using the new reaction rates following this.

The ZacrosSteadyStateJob.Parameters object allows to set the grid of

maximum times to explore in order to reach the steady state

(ss_params). Finally, we create ZacrosSteadyStateJob, which

references the ZacrosJob defined above (z_job) as well as the

Settings object and parameters we just defined:

ss_sett = pz.Settings()

ss_sett.turnover_frequency.confidence = 0.95

ss_sett.turnover_frequency.nreplicas = 4

ss_sett.scaling.enabled = 'T'

ss_sett.scaling.max_time = 60*1e-5

ss_params = pz.ZacrosSteadyStateJob.Parameters()

ss_params.add( 'max_time', 'restart.max_time',

2*z_sett.max_time*( numpy.arange(10)+1 )**2 )

ss_job = pz.ZacrosSteadyStateJob( settings=ss_sett, reference=z_job,

parameters=ss_params )

[27.01|09:15:05] JOB plamsjob Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

3. Setting up the ZacrosParametersScanJob

Although the ZacrosParametersScanJob does not require a Setting

object, it does require a ZacrosSteadyStateJob.Parameters object to

specify which parameters must be modified systematically. In this

instance, all we need is a dependent parameter, the \(O_2\) molar

fraction x_O2, and an independent parameter, the \(CO\) molar

fraction x_CO, which ranges from 0.05 to 0.95. Keep in mind that the

condition x_CO+x_O2=1 must be met. These molar fractions will be

used internally to replace molar fraction.CO and

molar fraction.O2 in the Zacros input files. Then, using the

ZacrosSteadyStateJob defined earlier (ss job) and the parameters

we just defined (ps params), we create the

ZacrosParametersScanJob:

ps_params = pz.ZacrosParametersScanJob.Parameters()

ps_params.add( 'x_CO', 'molar_fraction.CO', numpy.linspace(0.05, 0.95, 11) )

ps_params.add( 'x_O2', 'molar_fraction.O2', lambda params: 1.0-params['x_CO'] )

ps_job = pz.ZacrosParametersScanJob( reference=ss_job, parameters=ps_params )

[27.01|09:15:05] JOB ps_cond000 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond001 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond002 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond003 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond004 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond005 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond006 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond007 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond008 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond009 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

[27.01|09:15:05] JOB ps_cond010 Steady State Convergence: Using nbatch=20,confidence=0.95,ignore_nbatch=1,nreplicas=4

The parameters scan calculation setup is ready. Therefore, we can start

it by invoking the function run(), which will provide access to the

results via the results variable after it has been completed. The

sentence involving the method ok(), verifies that the calculation

was successfully executed, and waits for the completion of every

executed thread. Go and grab a cup of coffee, this step will take around

15 mins!

results = ps_job.run()

if not ps_job.ok():

print('Something went wrong!')

[27.01|09:15:05] JOB plamsjob STARTED

[27.01|09:15:05] Waiting for job plamsjob to finish

[27.01|09:15:05] JOB plamsjob RUNNING

[27.01|09:15:05] JOB plamsjob/ps_cond000 STARTED

[27.01|09:15:05] JOB plamsjob/ps_cond001 STARTED

[27.01|09:15:05] JOB plamsjob/ps_cond002 STARTED

...

[27.01|09:31:03] species TOF error ratio conv?

[27.01|09:31:03] CO -52.52688 4.84537 0.09225 False

[27.01|09:31:03] O2 -26.90450 2.78063 0.10335 False

[27.01|09:31:03] CO2 52.91640 4.65244 0.08792 False

[27.01|09:31:03] Replica #2

[27.01|09:31:03] species TOF error ratio conv?

[27.01|09:31:04] CO -225.40015 12.98476 0.05761 False

[27.01|09:31:04] O2 -115.66183 4.44209 0.03841 True

[27.01|09:31:04] CO2 228.95111 8.73665 0.03816 True

[27.01|09:31:04] Average

[27.01|09:31:04] species TOF error ratio conv?

[27.01|09:31:04] CO -54.87733 1.63967 0.02988 True

[27.01|09:31:04] O2 -26.85096 1.08631 0.04046 True

[27.01|09:31:04] CO2 54.73375 1.56100 0.02852 True

[27.01|09:31:04] JOB plamsjob/ps_cond000 Steady State Convergence: CONVERGENCE REACHED. DONE!

[27.01|09:31:04] JOB plamsjob/ps_cond000 FINISHED

[27.01|09:31:05] Replica #3

[27.01|09:31:05] species TOF error ratio conv?

[27.01|09:31:05] CO -216.58663 13.48940 0.06228 False

[27.01|09:31:05] O2 -106.99160 5.19478 0.04855 True

[27.01|09:31:05] CO2 214.75940 10.88629 0.05069 False

[27.01|09:31:06] Average

[27.01|09:31:06] species TOF error ratio conv?

[27.01|09:31:06] CO -221.49798 5.07706 0.02292 True

[27.01|09:31:06] O2 -110.17810 2.42785 0.02204 True

[27.01|09:31:06] CO2 220.65690 4.39982 0.01994 True

[27.01|09:31:06] JOB plamsjob/ps_cond010 Steady State Convergence: CONVERGENCE REACHED. DONE!

[27.01|09:31:06] JOB plamsjob/ps_cond010 FINISHED

[27.01|09:31:06] JOB plamsjob/ps_cond000 SUCCESSFUL

[27.01|09:31:07] JOB plamsjob/ps_cond010 SUCCESSFUL

[27.01|09:31:11] JOB plamsjob FINISHED

[27.01|09:31:15] JOB plamsjob SUCCESSFUL

If the execution got up to this point, everything worked as expected. Hooray!

Finally, in the following lines, we just nicely print the results in a

table. See the API documentation to learn more about how the results

object is structured, and the available methods. In this case, we use

the turnover_frequency() and average_coverage() methods to get

the TOF for the gas species and average coverage for the surface

species, respectively. Regarding the latter one, we use the last ten

steps in the simulation to calculate the average coverages.

x_CO = []

ac_O = []

ac_CO = []

TOF_CO2 = []

results_dict = results.turnover_frequency()

results_dict = results.average_coverage( last=10, update=results_dict )

for i in range(len(results_dict)):

x_CO.append( results_dict[i]['x_CO'] )

ac_O.append( results_dict[i]['average_coverage']['O*'] )

ac_CO.append( results_dict[i]['average_coverage']['CO*'] )

TOF_CO2.append( results_dict[i]['turnover_frequency']['CO2'] )

print( '------------------------------------------------' )

print( '%4s'%'cond', '%8s'%'x_CO', '%10s'%'ac_O', '%10s'%'ac_CO', '%12s'%'TOF_CO2' )

print( '------------------------------------------------' )

for i in range(len(x_CO)):

print( '%4d'%i, '%8.2f'%x_CO[i], '%10.6f'%ac_O[i], '%10.6f'%ac_CO[i], '%12.6f'%TOF_CO2[i] )

------------------------------------------------

cond x_CO ac_O ac_CO TOF_CO2

------------------------------------------------

0 0.05 0.665594 0.028219 54.733748

1 0.14 0.615375 0.082844 135.299544

2 0.23 0.582250 0.126594 198.215992

3 0.32 0.532375 0.178719 257.936395

4 0.41 0.497031 0.221625 300.382949

5 0.50 0.442750 0.272969 329.214754

6 0.59 0.402031 0.318562 352.259276

7 0.68 0.351687 0.372437 351.805662

8 0.77 0.297906 0.422687 332.247334

9 0.86 0.232156 0.488156 310.444388

10 0.95 0.144281 0.554344 220.656898

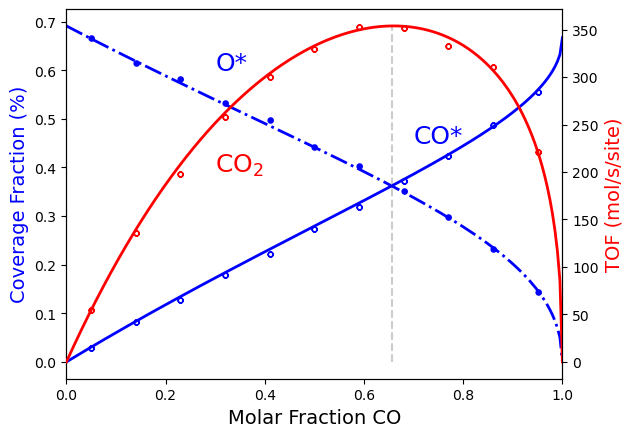

The results table above demonstrates that when \(CO\) coverage rises, the net \(CO\) oxidation reaction tends to progress more quickly until it reaches a maximum of about 0.7. At this point, it begins to decline. Notice that the maximal \(CO_2\) generation occurs simultaneously as the \(CO*\) coverage reaches parity with the \(O*\) coverage. This makes intuitive sense since, at that point, we maximize the likelihood of discovering an \(O*\) and a \(CO*\) that are close enough to react in accordance with the proper reaction’s stoichiometry. The number of \(O*\) or \(CO*\) observers rises as we move away from that critical point, decreasing the likelihood that the \(CO\) oxidation process could take place.

Now, we can close the pyZacros environment:

scm.pyzacros.finish()

[27.01|09:31:31] PLAMS run finished. Goodbye

Comparing with Traditional Kinetic Models¶

Note

To follow the second part of this tutorial, either:

Download

CoveragesAndReactionRate_ViewResults.py(run as$AMSBIN/amspython CoveragesAndReactionRate.py).Download

CoveragesAndReactionRate_ViewResults.ipynb(see also: how to install Jupyterlab)

The goal of this second part of the tutorial is to demonstrate how to

resume the calculation from the first part and visualize the results. In

addition, we will compare these results to an analytical model to assess

their quality. Before we begin, make sure we have the working directory

generated by CoverageAndReactionRate.ipynb or

CoverageAndReactionRate.py. We’ll assume it’s called

plams_workdir, which is the default value. However, keep in mind

that each time you run any of the above scripts, PLAMS will create a new

working directory by appending a sequential number to its name, for

example, plams_workdir.001. If this is the case, simply replace

plams_workdir with the appropriate value.

So, let’s get started!

First, we load the required packages and retrieve the

ZacrosParametersScanJob (job) and corresponding results object

(results) from the working directory, as shown below:

import scm.pyzacros as pz

import scm.pyzacros.models

scm.pyzacros.init()

job = scm.pyzacros.load( 'plams_workdir/plamsjob/plamsjob.dill' )

results = job.results

scm.pyzacros.finish()

PLAMS working folder: /home/user/pyzacros/examples/ZiffGulariBarshad/plams_workdir.002

[27.01|09:45:00] PLAMS run finished. Goodbye

To be certain, we generate and print the same summary table from the end of the first part of the tutorial. They must be exactly the same:

x_CO = []

ac_O = []

ac_CO = []

TOF_CO2 = []

results_dict = results.turnover_frequency()

results_dict = results.average_coverage( last=10, update=results_dict )

for i in range(len(results_dict)):

x_CO.append( results_dict[i]['x_CO'] )

ac_O.append( results_dict[i]['average_coverage']['O*'] )

ac_CO.append( results_dict[i]['average_coverage']['CO*'] )

TOF_CO2.append( results_dict[i]['turnover_frequency']['CO2'] )

print( '------------------------------------------------' )

print( '%4s'%'cond', '%8s'%'x_CO', '%10s'%'ac_O', '%10s'%'ac_CO', '%12s'%'TOF_CO2' )

print( '------------------------------------------------' )

for i in range(len(x_CO)):

print( '%4d'%i, '%8.2f'%x_CO[i], '%10.6f'%ac_O[i], '%10.6f'%ac_CO[i], '%12.6f'%TOF_CO2[i] )

------------------------------------------------

cond x_CO ac_O ac_CO TOF_CO2

------------------------------------------------

0 0.05 0.665594 0.028219 54.733748

1 0.14 0.615375 0.082844 135.299544

2 0.23 0.582250 0.126594 198.215992

3 0.32 0.532375 0.178719 257.936395

4 0.41 0.497031 0.221625 300.382949

5 0.50 0.442750 0.272969 329.214754

6 0.59 0.402031 0.318562 352.259276

7 0.68 0.351687 0.372437 351.805662

8 0.77 0.297906 0.422687 332.247334

9 0.86 0.232156 0.488156 310.444388

10 0.95 0.144281 0.554344 220.656898

Additionally, you can see the aforementioned results visually if you have installed the package matplotlib. Please review the code below.

import matplotlib.pyplot as plt

fig = plt.figure()

ax = plt.axes()

ax.set_xlim([0.0, 1.0])

ax.set_xlabel('Molar Fraction CO', fontsize=14)

ax.set_ylabel('Coverage Fraction (%)', color='blue', fontsize=14)

ax.plot(x_CO, ac_O, marker='$\u25CF$', color='blue', linestyle='-.', markersize=4, zorder=2)

ax.plot(x_CO, ac_CO, marker='$\u25EF$', color='blue', markersize=4, zorder=4)

plt.text(0.3, 0.60, 'O*', fontsize=18, color='blue')

plt.text(0.7, 0.45, 'CO*', fontsize=18, color='blue')

ax2 = ax.twinx()

ax2.set_ylabel('TOF (mol/s/site)',color='red', fontsize=14)

ax2.plot(x_CO, TOF_CO2, marker='$\u25EF$', color='red', markersize=4, zorder=6)

plt.text(0.3, 200.0, 'CO$_2$', fontsize=18, color='red')

plt.show()

Starting from the left side of the figure, it shows that by increasing

the x_CO; the net \(CO\) oxidation reaction tends to progress

more quickly (like a first-order reaction). Then the reaction rate peaks

at around x_CO=0.7, becoming almost independent of x_CO (like a

zero-order reaction). And finally, it then begins to decline (like a

negative-order reaction). Furthermore, we can see that as we increase

the coverage of \(CO*\), we decrease the coverage of \(O*\). As

a result, when we mostly cover the surface with one of the reactants

(either \(CO*\) or \(O*\)), the rate of \(CO_2\) production

becomes slow because there isn’t enough of the complementary reactant on

the surface. So, it is not a surprise, that the maximum \(CO_2\)

generation coincides with the point at which \(CO*\) coverage equals

\(O*\) coverage.

In the Zacros tutorial What’s KMC All About and Why Bother?, there is a thorough discussion of Langmuir-Hinshelwood-type models, their approximations with respect to a real system, and how to obtain analytical expressions for reactant coverages and the net reaction rates concerning gas phase composition. In particular, these expressions are reached by making the fundamental assumption that both diffusion and adsorption/desorption events are quasi-equilibrated (being the later one the rate-limiting factor), occurring on a much faster timescale than the oxidation event. We use the same argument to speed up our calculations. Thus, we can use the analytical expressions we obtained to assess the overall quality of our results. Our results should be indistinguishable from the Langmuir-Hinshelwood deterministic equations, which are shown below:

Here \(B_\text{CO}\)/\(B_{\text{O}_2}\) represent the ratio of

the adsorption-desorption pre-exponential terms of

\(CO\)/\(O_2\) (pe_ratio in Zacros),

\(x_\text{CO}\)/\(x_{\text{O}_2}\) the molar fractions of

\(CO\)/\(O_2\); \(\theta_\text{CO}\)/\(\theta_\text{O}\)

the coverage of \(CO*\)/\(O*\), \(A_\text{oxi}\) the

pre-exponential factor of the CO oxidation step (pre_expon in

Zacros), and TOF\(_{\text{CO}_2}\) the turnover frequency or

production rate of \(CO_2\). The number 6 is because, in our

lattice, each site has 6 neighbors, so the oxidation event is

“replicated” across each neighboring site.

Notice that to get the above expressions based on the ones shown in the Zacros tutorial, you need the following equalities:

The final equality follows from the fact that in pyZacros, the activation energy for all elementary reactions is equal to zero.

The code below simply computes the coverages and TOF of \(CO_2\) using the analytical expression described above:

import numpy

lh = pz.models.LangmuirHinshelwood()

B_CO = lh.mechanism.find_one( 'CO_adsorption' ).pe_ratio

B_O2 = lh.mechanism.find_one( 'O2_adsorption' ).pe_ratio

A_oxi = lh.mechanism.find_one( 'CO_oxidation' ).pre_expon

x_CO_model = numpy.linspace(0.0,1.0,201)

ac_O_model = []

ac_CO_model = []

TOF_CO2_model = []

for i in range(len(x_CO_model)):

x_O2 = 1 - x_CO_model[i]

ac_O_model.append( numpy.sqrt(B_O2*x_O2)/( 1 + B_CO*x_CO_model[i] + numpy.sqrt(B_O2*x_O2) ) )

ac_CO_model.append( B_CO*x_CO_model[i]/( 1 + B_CO*x_CO_model[i] + numpy.sqrt(B_O2*x_O2) ) )

TOF_CO2_model.append( 6*A_oxi*ac_CO_model[i]*ac_O_model[i] )

Additionally, if you have installed the package matplotlib, you can see the aforementioned results visually. Please look over the code below, and notice we plot the analytical and simulation results together. The points in the figure represent simulation results, while the lines represent analytical model results. They are nearly identical.

import matplotlib.pyplot as plt

x_CO_max = (B_O2/B_CO**2/2.0)*(numpy.sqrt(1.0+4.0*B_CO**2/B_O2)-1.0)

fig = plt.figure()

ax = plt.axes()

ax.set_xlim([0.0, 1.0])

ax.set_xlabel('Molar Fraction CO', fontsize=14)

ax.set_ylabel('Coverage Fraction (%)', color='blue', fontsize=14)

ax.vlines( x_CO_max, 0, max(ac_O_model), colors='0.8', linestyles='--',)

ax.plot(x_CO_model, ac_O_model, color='blue', linestyle='-.', lw=2, zorder=1)

ax.plot(x_CO, ac_O, marker='$\u25CF$', color='blue', lw=0, markersize=4, zorder=2)

ax.plot(x_CO_model, ac_CO_model, color='blue', linestyle='-', lw=2, zorder=3)

ax.plot(x_CO, ac_CO, marker='$\u25EF$', color='blue', markersize=4, lw=0, zorder=4)

plt.text(0.3, 0.60, 'O*', fontsize=18, color='blue')

plt.text(0.7, 0.45, 'CO*', fontsize=18, color='blue')

ax2 = ax.twinx()

ax2.set_ylabel('TOF (mol/s/site)',color='red', fontsize=14)

ax2.plot(x_CO_model, TOF_CO2_model, color='red', linestyle='-', lw=2, zorder=5)

ax2.plot(x_CO, TOF_CO2, marker='$\u25EF$', color='red', markersize=4, lw=0, zorder=6)

plt.text(0.3, 200.0, 'CO$_2$', fontsize=18, color='red')

plt.show()

As a final note, we included in the code above the value of the \(CO\) molar fraction (\(x_\text{CO}^*\)) on which we get the maximum \(CO_2\) production rate. The figure shows this value as a vertical gray dashed line. It is simple to deduce it from the preceding analytical expressions:

Notice that the position of this maximum \(x_\text{CO}*\) depends

exclusively on the ratio of the pe_ratio parameters for \(CO\)

and \(O_2\) in the Langmuir-Hinshelwood model.